10 Essential Tools to Simplify and Enhance Welders’ Tasks

Posted by Koike Aronson, Inc. on Dec 20th 2024

Welding is a combination of art and science that requires precision, skill, and a quality set of tools. For welders, having the right equipment makes the difference between a good job and an excellent one. Whether you’re a welding beginner or certified by the American Welding Society, the tools you use can considerably impact your efficiency and the quality of your work. Explore the tools that will make a welder’s life easier.

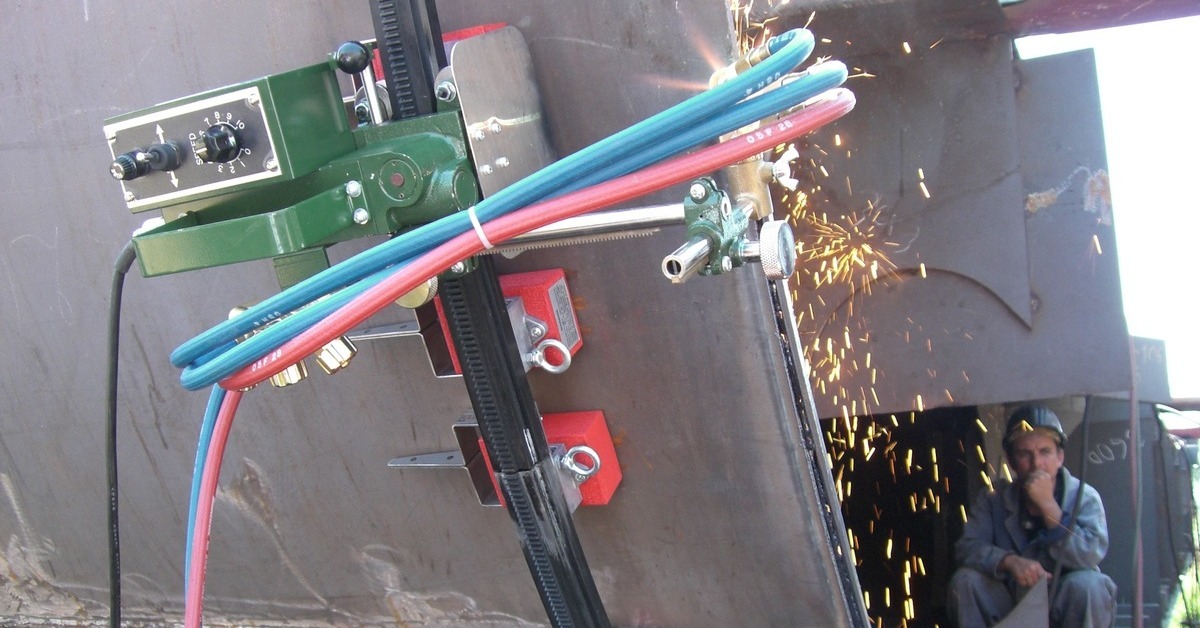

Portable Track-Guided Cutters

Precision cutting is essential for ensuring proper fit-up and alignment of welded joints. Portable track cutters create clean, accurate cuts, allowing for better fit-up in weld joints and minimizing post-cut grinding.

A track guides these machines. The cutters follow the path to execute precise cuts. The machine’s portability also means they can be used wherever the job demands, such as on jobsites and in the shop.

Track-guided cutters are also exceptionally versatile. They work well for materials of varying thicknesses so welders can use these tools for many applications.

Pro Tip

For the cleanest, most accurate cuts with a portable track cutter, make sure the track is free of debris before each cut. Even small particles can disrupt the cutter’s path, leading to minor imperfections that will require additional grinding.

Additionally, calibrate the cutter’s speed setting based on material thickness to prevent overheating and warping. This is especially important for thinner metals. A careful setup will administer precise, smooth cuts with minimal finishing required.

Track-Guided Welding Systems

Precision is crucial in welding, especially for long and continuous welds. Manufacturers design track-guided systems to help welders achieve consistent, accurate results. These tools use a mechanized carriage that runs along a track while simultaneously controlling the welding torch’s movement.

One of the main advantages of track-guided systems is their ability to produce high-quality welds with minimal effort. The guided track ensures the torch moves at a consistent speed and angle, reducing the risk of errors and inconsistencies.

Portable Trackless Fillet Welding Carriage

A portable trackless fillet welding carriage is a game-changer for welders because it supplies unmatched precision and efficiency to fillet welds without the need for track setup. Designed to move freely along a workpiece, these carriages follow a set path to conduct consistent, high-quality welds on horizontal and vertical surfaces. This type of carriage reduces the chance of error with features such as adjustable speed settings and angle adjustments. Therefore, welders can focus on weld integrity while reducing the need for reworking pieces.

The portability of a trackless carriage means it’s not only versatile for on-site work but also perfect for various shop applications. By automating the carriage’s movement, welders experience less fatigue and can produce uniform welds more quickly, making it an essential tool for projects requiring both speed and precision.Welding Positioners

Welding positioners are invaluable for holding workpieces in place, reducing the need for manual handling. They allow welders to maintain ergonomic positions and complete welds without awkward bending or reaching, which also improves safety by reducing the chance of accidents when repositioning a weldment. Here are a few types of welding positioners that can elevate a welder’s efficiency and safety:

- Turntables: These provide 360-degree access to a workpiece, enabling welders to adjust the weldment to the desired position without the need for long torch leads or moving the welding equipment.

- Tilt/turn positioners: These versatile devices allow for both tilting and rotating so welders can easily access multiple sides of a workpiece.

- Turning rolls: Designed to hold cylindrical objects, pipe positioners stabilize workpieces, making them ideal for tasks requiring precision, including pipe welding.

Ergonomic characteristics are particularly important when welders handle large, heavy-duty materials. With these tools, welders can execute high-quality welds with reduced physical strain. By securely holding the workpiece, the positioners improve both efficiency and safety, allowing welders to focus on each task without risking injury from manual repositioning.

Welding Manipulators

Welding manipulators are designed to enhance accuracy in challenging welds, especially those requiring consistent speed and angle. By moving the welding torch along a controlled axis, manipulators automate the torch’s movement to conduct precise and uniform welds.

For instance, in situations where repetitive welding is necessary, manipulators save time and prevent errors by maintaining consistent settings. Welders can focus on setup and oversight rather than physically performing each weld. This is particularly useful for complex or high-volume projects. Koike Aronson has welding positioners for sale in addition to other essential equipment for your workshop.

Quick Connect Gas Couplers

Quick connect gas couplers allow welders to swiftly and safely set up and change tools such as hand torches and welding machines. By eliminating the need for time-consuming unscrewing and re-screwing of hoses, couplers reduce setup time and enable fast tool-switching on the job. Quick connects are perfect for multistep projects where efficiency and flexibility are key.

Many gas couplers include additional safety features such as check valves that prevent reverse flow in the event of a flashback for an extra layer of protection for the welder. Another useful feature is the automatic gas shut-off; it prevents gas waste by keeping gases contained within the hoses. These added functionalities make quick connect couplers not only time-savers but also safer, more economical choices for welding setups.

Angle Grinder

An angle grinder is another tool that makes a welder’s life easier. This versatile tool grinds, cuts, and polishes metal surfaces, allowing professionals to clean up rough welds and smooth out imperfections. Welders can also use angle grinders for metal shaping, removing rust or scale, and cutting through thick metal pieces.

Welding Table or Workbench

Having a sturdy and reliable welding table is the foundation of any welding project. Welding tables provide a stable platform for the workpiece, allowing welders to focus on the task at hand without worrying about stability or positioning. They also come with various clamps and fixtures that can hold metal pieces of different shapes and sizes securely.

Welding Safety Gear

Safety is a priority in welding. A collection of safety gear is essential for protecting yourself from potential hazards. Every welder should own the following safety items:

Welding Jacket

The temperatures emitted from torches can reach several thousand degrees. A welding jacket protects your upper body from sparks, spatter, and heat. With durable materials like leather or flame-resistant fabric, you have a strong barrier safeguarding your body against burns and injuries.

Gloves

Welding gloves prevent burns and cuts when working with hot metal pieces, welding rods, and other equipment. Shop for thick, fully leather gloves for maximum protection. Make sure they fit snugly so you can meticulously handle each piece of welding equipment.

Steel-Toed Boots

Steel-toed boots provide essential protection for your feet in the welding environment. They prevent injuries from falling objects, sharp metal, and hot surfaces.

Auto-Darkening Welding Helmet

A welding helmet protects the face and eyes from UV radiation, sparks, and debris. Unlike traditional helmets that need to be manually lifted and lowered, auto-darkening helmets adjust automatically, switching from a light to dark shade the moment an arc is struck.

Welding Accessories

In addition to primary tools and safety gear, various accessories can improve each project’s efficiency and quality. Accessories that every welder should have include:

Welding Pliers

Welding pliers combine multiple functions, such as gripping, cutting, hammering, and cleaning, into a single, convenient tool. They are perfect for tasks such as removing hot nozzles, cleaning contact tips, and cutting wire. You never know when you’ll need them, so always keep the pliers near your workstation during projects.

Chipping Hammer

You’ll need a chipping hammer to remove slag from welds and to produce a clean finish. By cleaning up the weld immediately, the welder can inspect it for any potential flaws or areas that need additional work. This tool typically has a pointed end and a chiseled end, allowing you to tackle different cleaning tasks.

Welding Clamps

Welding clamps are crucial for securing workpieces. They offer stability and alignment for precise, consistent welds. Various clamps are available—such as C-clamps, locking pliers, and magnetic clamps—for a wide range of welding applications.

Wire Brush

A wire brush is necessary to clean and prepare surfaces before welding. The tool can remove rust, paint, and other debris from metal and your workstation. Clearing away these contaminants using the wire brush ensures that you don’t damage your welds.

Sheet Metal Gauge

A sheet metal gauge is a handy tool for measuring the thickness of metal sheets. Accurate measurements are crucial for selecting the appropriate welding settings and materials.

Marking Tools

Marking tools—such as markers or soapstone—clearly mark areas on the metal. These simple resources guide you to make precise welds, cuts, and more.

Shop for High-Quality Tools

Koike Aronson, Inc. has over 100 years of experience in welding and metalworking, providing top-quality equipment and welding solutions to businesses. We offer an extensive range of tools and accessories for all your welding needs. With our commitment to innovation, durability, and safety, you’ll find the high-quality welding tools you need from our online store.