6 Ways To Increase the Lifespan of Your Welding Equipment

Posted by Koike Aronson, Inc. on Dec 9th 2024

Welding equipment isn’t cheap, but it is a valuable investment for any welding professional or company. Certain practices can ensure that you get the most out of your equipment and maximize its lifespan. These tasks range from keeping gear clean to investing in quality tools. Here are the top ways to increase the lifespan of your welding equipment.

Keep It Clean

Welding environments are messy, and metal dust finds its way into your equipment. Wipe down your machines regularly to prevent dirt from building up.

Use compressed air to clean the harder-to-reach areas. Likewise, compressed air can help loosen stubborn dirt or debris. However, you should avoid using high-pressure air, as it can damage delicate parts of the equipment.

Perform Regular Inspections

While cleaning your tools, you should also inspect each component—cables, hoses, connections, and torches—for signs of damage. Replace any damaged parts immediately to avoid further damage or potential hazards.

Moreover, regularly inspecting your equipment can help you identify potential issues before they become significant problems. Early detection and prompt action in addressing equipment issues ensure your welding equipment’s longevity and optimal performance. Never use welding equipment with damaged components, as this can lead to injury and costly repairs.

Replace Contact Tips

Contact tips help conduct the electrical current to the welding wire. Over time, contact tips wear out, leading to poor welding quality. As these components wear out, you may notice inconsistent arc and spatter or difficulty maintaining a stable arc.

Evaluate Cable Connections

Loose or damaged cables can cause power loss and poor weld quality. When inspecting cables, check for any signs of fraying or cuts in the insulation.

Contact the Manufacturer

If you notice problems with your welding equipment that you can’t fix, contact the manufacturer for assistance. They can provide expert advice and solutions to address any issues with your equipment.

Keep Software Updated

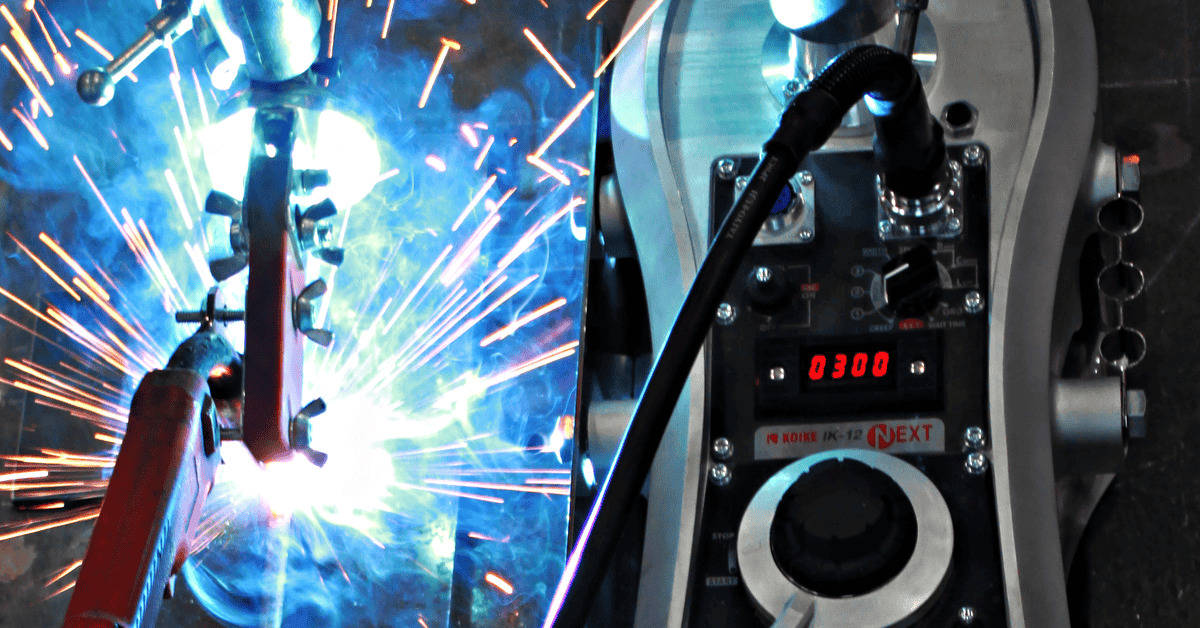

Nowadays, many welding tools are machine-powered, so operators can set up the machine and adjust settings to their preferences. Due to this, machines come with specific software that requires regular updates. Neglecting software updates can lead to glitches, unstable performance, and reduced equipment lifespan.

Pro Tip

Set a schedule to check for available updates, and apply them as soon as possible. Once you’ve updated the software, test the equipment to ensure it functions correctly.

Properly Store All Parts

Properly storing components is another way to increase the lifespan of your welding equipment. Store your equipment in a clean, dry environment to prevent rust and corrosion. Avoid exposing your equipment to extreme temperatures or humidity, which can damage delicate components.

Additionally, storing parts separately can prevent them from rubbing against each other, causing wear and tear. If you’re using a welding cart, ensure it has proper ventilation and space for each part to avoid overheating.

Pro Tip

Organize your storage area to ensure easy access to all parts and tools. Label the storage containers for quick identification.

Follow Manufacture Guidelines

When buying a new tool, you should always read the manufacturer’s guidelines and recommendations. The manual outlines important maintenance procedures and usage instructions that can help extend the lifespan of your equipment. Failure to follow these guidelines can result in damage or potential safety hazards.

Keep in mind that all machines are different, and a manufacturer may have different care procedures for each tool they sell. Similarly, every maker will have distinct care recommendations based on the specifics of their equipment.

Ensure all operators at your company understand how to use each tool. You may want to hold annual training sessions so that workers always use welding equipment properly.

Pro Tip

Following these guidelines may also require maintaining any warranties or guarantees on your equipment.

Invest in Quality

Investing in high-quality welding equipment pays off in the long run, as well-made tools often require less maintenance and last longer. When purchasing welding equipment, consider the manufacturer’s reputation and reviews from other users.

Moreover, high-quality equipment often comes with better warranties and customer support, which can save you money on repairs and replacements. Likewise, quality customer service can provide helpful tips and troubleshoot any issues with your equipment.

For example, if you have a question about your welding machine’s settings, customer service can guide you through the process, which can prevent the risk of misusing gear.

What Makes Quality Welding Equipment?

The quality of the welding equipment used can significantly impact the efficiency and safety of the operation. As you shop for new welding tools, factors to consider include:

User-Friendly Build

Equipment that is easy to set up and operate allows welders to focus on their work without wasting time on complicated adjustments. Features like intuitive controls and clear displays simplify the welding process, making it accessible for welders of all skill levels. Welders should also be able to troubleshoot any issues during operation.

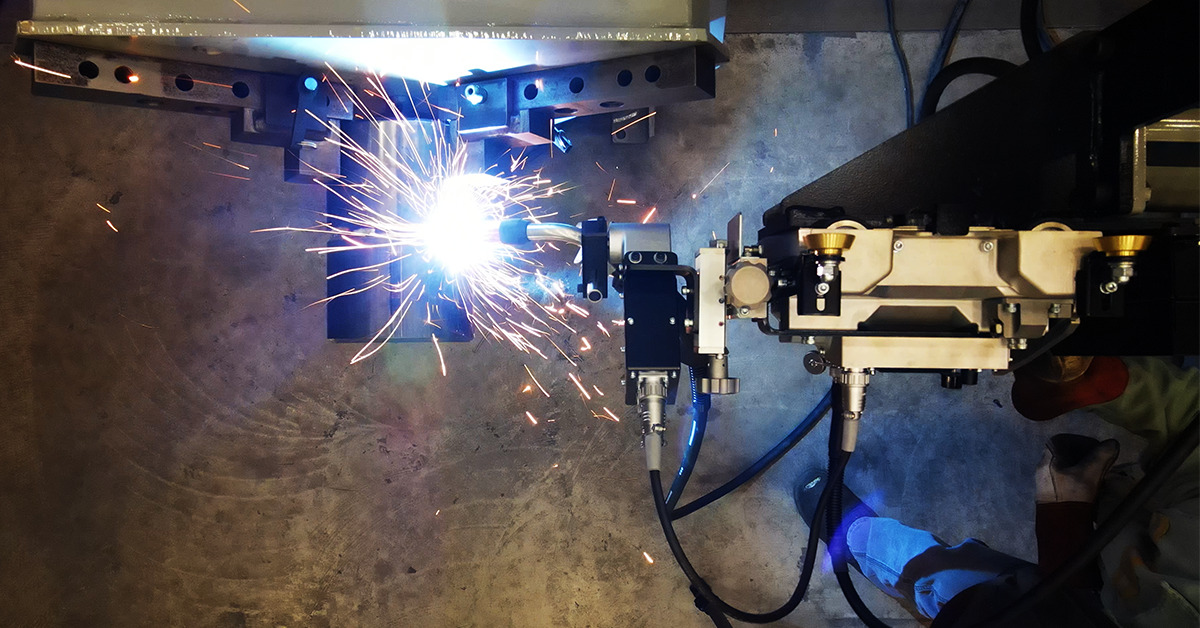

Durability

Manufacturers build high-quality welding equipment to withstand the wear and tear of daily use. This includes sturdy construction, resistant materials, and reliable components. Durable equipment can handle the demands of heavy-duty welding projects without breaking down or needing frequent repairs.

Advanced in Welding Technology

Welding technology continually evolves, bringing new and improved techniques and equipment to the industry. Staying current with these advancements can help you maintain your welding equipment better. By staying informed about technological developments, you can identify areas for improvement in your welding processes and invest in new tools when necessary.

A Reputable Seller

When purchasing welding equipment, it is essential to buy from the right manufacturer. A reliable seller will provide high-quality products and exceptional customer service. As you shop, read the reviews carefully for both the equipment you need and the company.

Look for sellers with positive reviews and a proven track record in the industry; long-standing companies are more likely to offer well-made equipment because of their years of expertise.

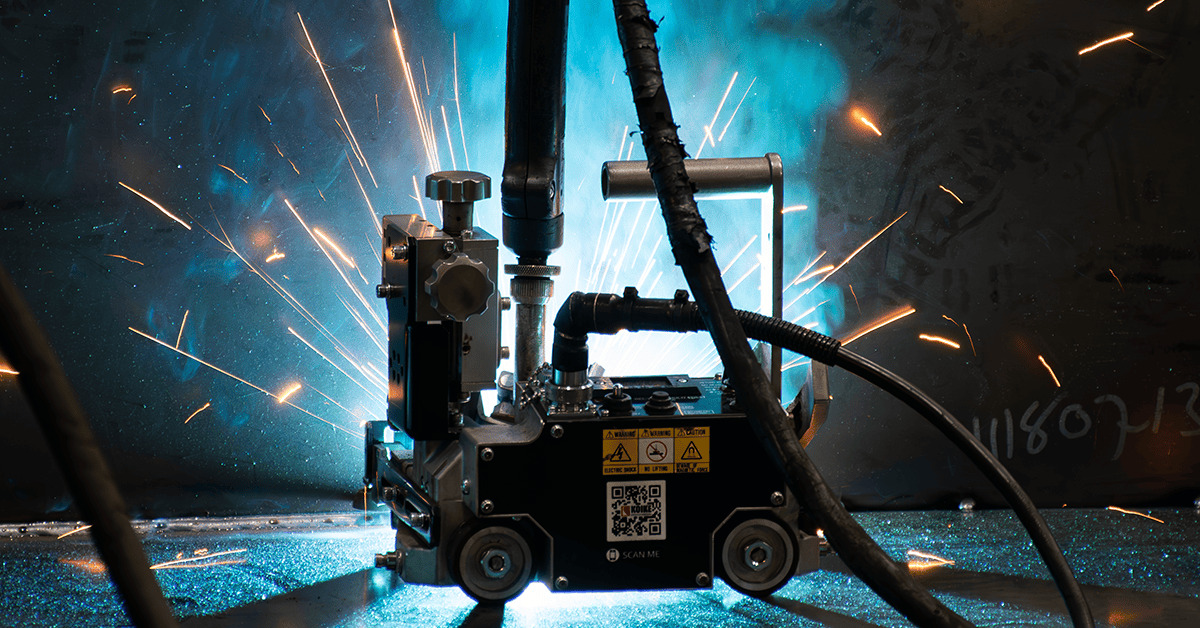

Order Your Welding Equipment

Investing in quality welding equipment ensures long-term benefits and reduces maintenance needs. Koike Aronson, a leading welding and cutting equipment manufacturer, offers a wide range of portable welding machines. With over 100 years of experience, Koike Aronson can provide exceptional customer service and reliable equipment for your welding needs. Explore our products today and start increasing the lifespan of your welding tools.