Beginner’s Guide to Operating Plasma Cutting Torches

Learning how to use a plasma cutting torch can be complicated for beginners, but with the proper knowledge and practice, it can be a valuable tool in various industries. Plasma cutting can cut various conductive metals like steel, stainless steel, aluminum, and copper. It's faster, especially on thinner metals, and doesn't require preheating, making it more efficient for high-speed and intricate applications. Plasma cutting is a versatile and powerful technology widely used across various industries because of its ability to cut conductive metals with speed and precision. From intricate metal designs to large-scale industrial applications, plasma cutting plays a crucial role in enhancing efficiency and accuracy. Five key areas where plasma cutting is essential are automotive repair, metal art, construction, manufacturing, and shipbuilding. Each of these applications demonstrates the broad utility of plasma cutting in shaping, fabricating, and maintaining metal components for diverse purposes.

This beginner’s guide to using plasma cutting torches provides a comprehensive understanding of plasma cutting torches, their processes, and applications.

What Is a Plasma Cutting Torch?

Plasma cutting is a process that uses a high-velocity jet of ionized gas (plasma) to cut through electrically conductive materials such as steel, stainless steel, aluminum, and copper. By generating an electrical arc and directing it through a gas, plasma cutters create intense heat that melts the metal, while the high-speed gas blows the molten material away, resulting in a clean cut. When setting up to use an air plasma cutting torch for the first time, please follow these important guidelines:

1. Safety First

- Wear protective gear: safety glasses, gloves, and a welding helmet.

- Ensure proper ventilation in your workspace.

2. Check the Power Supply

- Ensure your plasma cutter is plugged into the correct power outlet (e.g., 110V or 220V, depending on the model).

- Turn off the plasma cutter before making any connections.

3. Connect the Air Supply

- Attach the air compressor to the plasma cutter using the appropriate hose.

- Set the air pressure according to the manufacturer's specifications (usually around 60-70 psi).

4. Install the Torch

- Connect the plasma torch to the machine, ensuring all connections are secure.

- Confirm the correct consumables are in the torch for the material you will cut.

- Attach the ground clamp to your workpiece or workbench.

5. Set the Cutting Parameters

- Adjust the amperage on the plasma cutter based on the thickness of the material you’re cutting. Higher amperage is needed for thicker metals.

6. Position the Torch

- Hold the torch at a 90-degree angle to the workpiece.

- Start the torch slightly above the metal and maintain a consistent cutting distance (around 1/8 inch above the material).

7. Begin Cutting

- Pull the trigger to ignite the plasma arc.

- Move the torch slowly and steadily along the cutting line, maintaining a consistent speed for a clean cut. Maintaining a steady hand and consistent speed is important for achieving clean cuts with minimal slag or dross.

8. Shut Down and Clean Up

- Once done, turn off the plasma cutter.

- Disconnect the air supply and power.

- Clean the work area and store your tools properly.

Pro Tip

Koike Aronson offers numerous options for CNC plasma cutting machines and other portable tools that will make cutting through metal more efficient.

Common Uses for Plasma Cutting Torches

Numerous industries, including construction, manufacturing, metal fabrication, and automotive repair, rely on plasma cutting torches to cut metal. The exact cutting tools you should use depend on the cutting application, such as pipe, tank, and plate cutting.

Pipe Cutting

When cutting pipes, it is essential to secure the pipe properly to prevent movement. Insecure fastening can lead to uneven cuts and potential accidents. Using pipe clamps or vices can help maintain stability.

Tank Cutting

Because of the risk of flammable gases, it is crucial to follow safety protocols when cutting tanks. Proper ventilation and using explosion-proof equipment are necessary precautions. Additionally, marking the cut lines accurately ensures that the cuts are precise and reduces material wastage.

Plate Cutting

Plate cutting involves cutting flat metal sheets into desired shapes and sizes, which is common in manufacturing and construction industries. Maintain a consistent torch angle and distance from the plate and ensure you select the right cutting machine so that you can achieve clean cuts.

Common Types of Cutting

Hand-Guided Cutting

Hand-guided cutting requires skill and practice to achieve clean cuts. Holding the torch steady and maintaining a consistent speed is crucial. Wavering or inconsistent speed can result in jagged cuts and increased material wastage. Positioning the body comfortably and using both hands to guide the torch can improve control.

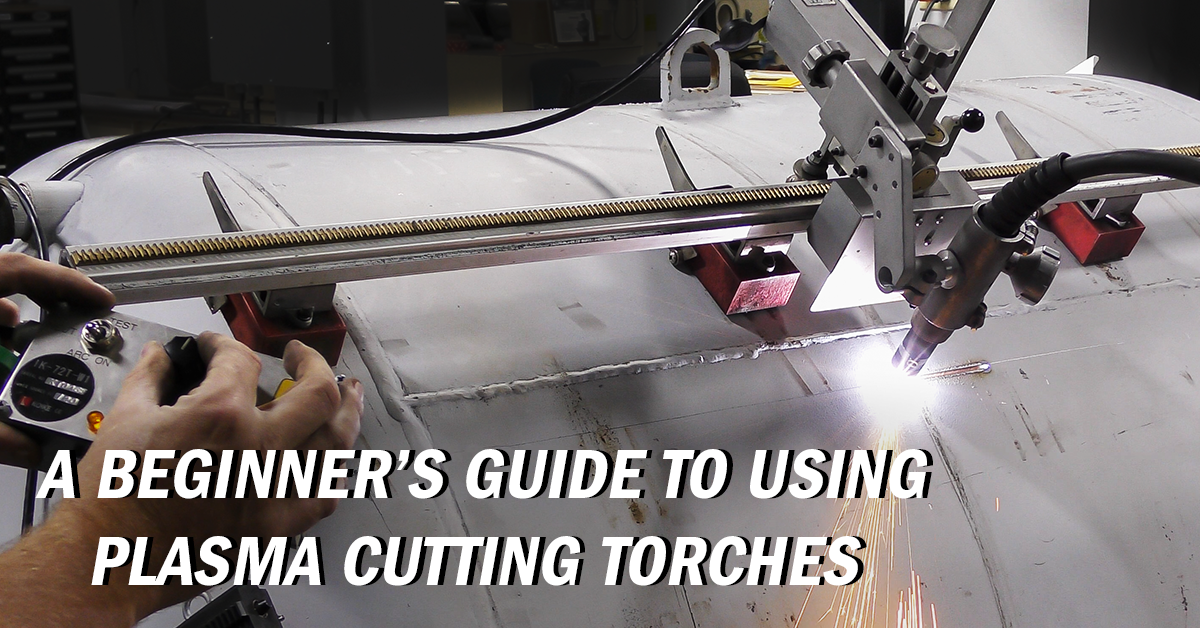

Track-Guided Cutting

Track-guided cutting involves using a mechanical guide to ensure straight and precise cuts. This method is ideal for cutting long sections of metal with consistent accuracy. Properly set up the track and ensure it remains aligned with the cut path. Moreover, using a track guide reduces the chances of human error and enhances cutting efficiency.

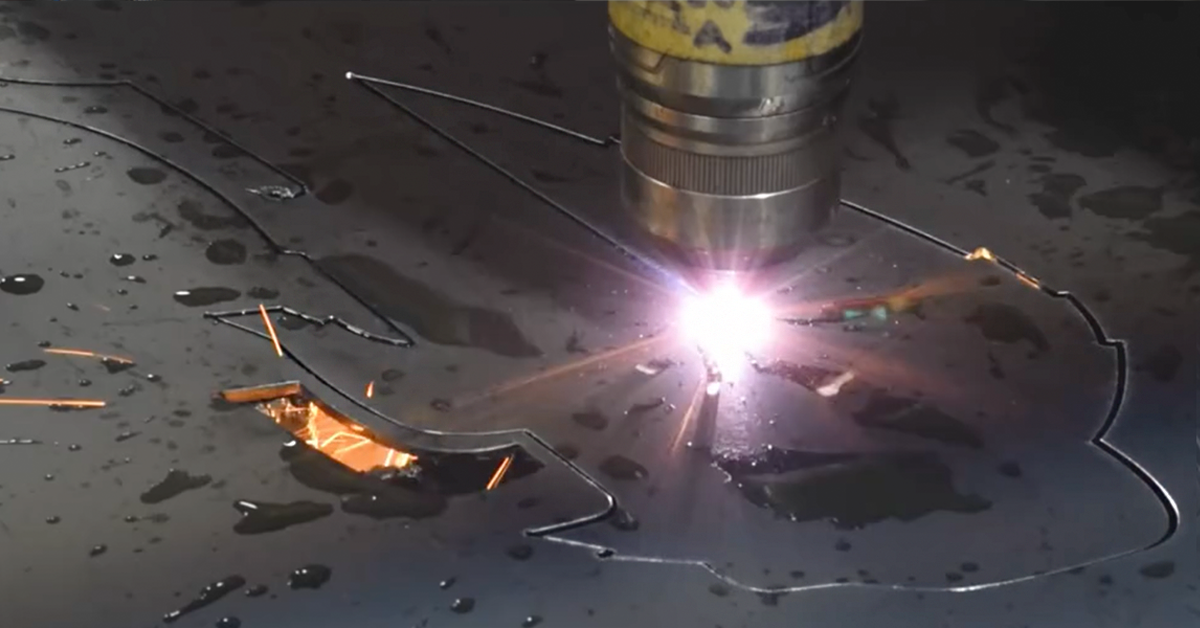

Shape Cutting

A CNC plasma cutting machine combines plasma cutting technology with computer numerical control (CNC) to automate the cutting process. This allows for precise, repeatable cuts on a wide range of conductive materials like steel and aluminum. CNC plasma cutting is ideal for producing complex shapes, detailed parts, and large-scale production with high accuracy and minimal human intervention, making it a valuable tool in manufacturing, metal fabrication, and industrial applications. A machine plasma cutting torch is a designed for use with CNC plasma cutting machines and is typically mounted on a mechanized system that controls its movement.

Tips for Using Plasma Cutting Torches

Getting familiar with your cutting torch and its specific settings is essential for efficient and safe operation. This means prioritizing safety, maintaining proper distance, mastering cutting techniques, and shopping for quality tools.

Prioritize Safety

No beginner’s guide to cutting torches is complete without a significant portion devoted to safety measures. The intense heat and open flame pose significant risks if not handled correctly. Before using a torch, always wear appropriate personal protective equipment (PPE). Some of the essential gear to wear includes:

Essential Safety Gear for Plasma Cutting:

- Safety Glasses or Welding Helmet – Protects eyes from sparks and bright light.

- Flame-Resistant Gloves – Shields hands from heat and molten metal.

- Fire-Resistant Clothing – Protects skin from sparks and heat.

- Hearing Protection – Reduces exposure to high noise levels.

- Proper Ventilation or Respirator – Ensures protection from fumes and smoke.

Moreover, regularly inspect your equipment for any signs of wear or damage. Faulty equipment can lead to dangerous situations, so maintaining your tools in good condition is essential for safe operation.

Maintain Appropriate Distance

When using a drag tip on a plasma hand cutting torch, the tip is designed to be in direct contact with the metal surface during cutting. This provides better control and stability, making it easier to follow cutting lines accurately. The drag tip allows the operator to maintain a consistent cutting distance, reducing the chance of errors. It is commonly used for straight-line cuts, tracing templates, or cutting shapes where precise control is essential, making it ideal for beginners or for cutting thin materials where smooth and accurate cuts are needed.

When using a standard tip, maintaining the correct distance between the torch tip and the metal as you make cuts ensures quality cuts. If you stand too far away, the cuts may not be clean, but if you’re too close, there’s a chance the metal will melt together and create more dross.

The ideal distance varies depending on the cutting tip type and thickness of the metal you’ll cut. Refer to your plasma torch user manual for specific guidelines based on the metal type and cutting method you’ll use.

Mastering Hand Cutting Techniques

Mastering the techniques involved in hand cutting with a torch takes practice and skill. For beginners, it’s best to start with simple cuts and gradually progress to more complex ones. Familiarize yourself with the different types of cuts, such as straight cuts, bevel cuts, and piercing. Learning to manipulate the torch’s angle and distance while cutting can help achieve different cuts.

Shop for Quality Machines

Purchasing a high-quality cutting machine can significantly improve your work. When browsing for cutting machines, consider the following key factors:

Key Factors To Consider When Buying a Quality CNC Plasma Cutting Machine:

- Cutting Capacity – Match the machine's amperage and cutting capacity to the thickness of materials you'll work with.

- Table Size – Ensure the cutting area accommodates the size of your projects.

- Software Compatibility – Check for user-friendly software and support for various file formats (e.g., DXF, DWG).

- Durability and Build Quality – Look for robust construction and reliable components for longevity.

- Precision and Accuracy – Ensure the machine delivers high accuracy for detailed cuts.

- Torch Quality – Consider the quality and type of plasma torch (manual or mechanized).

- Ease of Use – Look for intuitive controls and features that streamline setup and operation.

- Support and Warranty – Choose a machine with strong manufacturer support and a good warranty.

- Cost and Budget – Balance features and performance with your budget.

- Expandability – Ensure the machine can be upgraded or expanded as your needs grow.

It is also important to read reviews and compare prices from reputable suppliers before buying your plasma cutting equipment.

Shop at Koike Aronson

With over 100 years of industry experience, you can count on Koike Aronson for superior welding tools and support. As industry leaders, we are committed to providing our customers with the best quality equipment and service.