How CNC Machines Reduce Waste in Manufacturing | Koike

Every material you use is an asset when you work in the manufacturing industry. Wasting resources is not only financially detrimental but also negatively impacts the environment. Many companies use modern tools, such as computer numerical control machines, to maximize their use of materials. This guide details how CNC machines reduce waste in manufacturing.

Increased Precision

The creation of computer numerical control (CNC) machines has reduced the need for handheld cutting tools. Although manually operated tools, such as pantographs, are still helpful, they require a high skill level to operate effectively.

Many CNC machines rely on computer-aided design (CAD) software to program movements. Operators program CNC machines with exact specifications to ensure each cut or drilled hole aligns perfectly with design requirements. This precision translates into fewer mistakes during production and reduces the likelihood of scrapping materials due to cutting errors.

Facilitates Making Complex Cuts

Sometimes, a design calls for intricate and complex cuts, which can be difficult to achieve with manual tools. Due to their computerized nature, CNC machines can make complex and multi-dimensional cuts at a faster rate than even a skilled worker.

Consistency in Automation

Thanks to technological advancements, many tasks are now automated, reducing the risk of human error. Operators program CNC machines to perform repetitive tasks to ensure consistency in production. This also enables companies to produce identical parts at a faster rate than with traditional methods.

Moreover, CNC machines automate the reproduction of complex designs, expanding possibilities for product innovation and customization. For instance, if you manufacture parts for cars, you can produce identical parts with a CNC machine. They will fit perfectly and improve the vehicle’s overall quality.

Increased Quality Control

By improving consistency, you also boost quality control throughout the production process. Workers can spot issues or defects in manufacturing and make necessary adjustments before wasting additional resources on defective parts.

Real-Time Monitoring

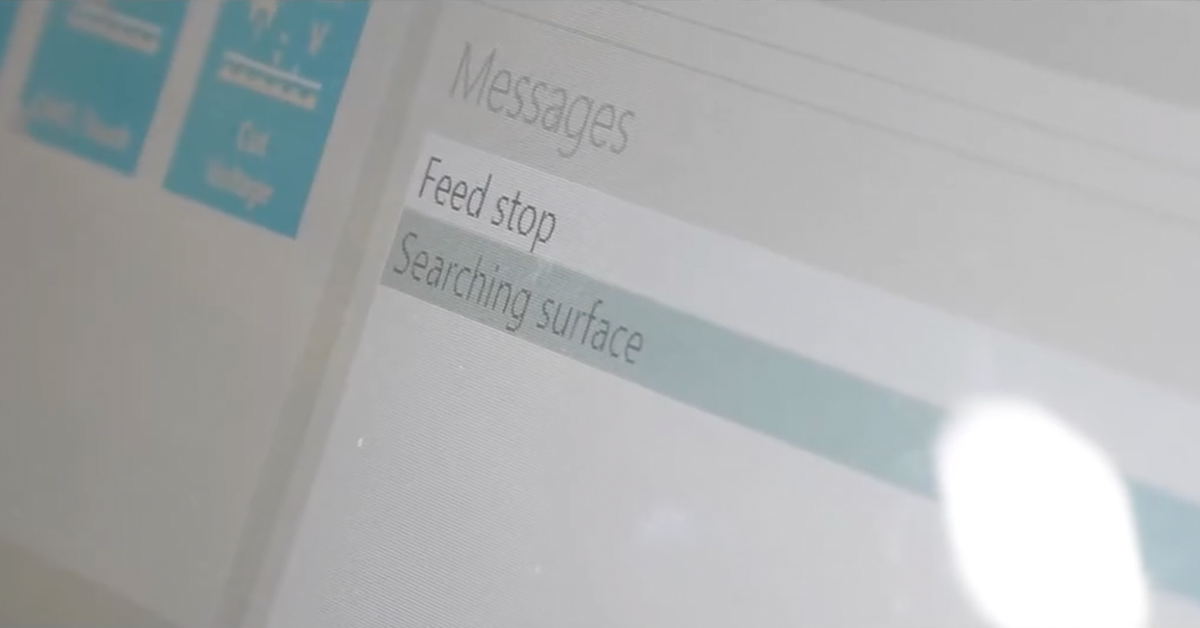

When using a CNC machine, operators can closely monitor the production process and make adjustments for the highest-quality output. If an issue arises, operators can quickly address it before it becomes a larger problem.

Additionally, the CNC machine can detect deviations from the programmed specifications, pause the production process, and alert operators to make adjustments. Then, workers can correct issues.

Energy Efficiency in Manufacturing

Using a CNC machine can also reduce energy consumption in manufacturing. Manually cutting all shapes takes a long time and requires more physical effort, which can result in higher energy consumption. CNC machines only consume the necessary energy to complete a task. This decreases energy usage and minimizes the environmental impact of manufacturing.

Furthermore, modern CNC machines have energy-saving features, such as automatic shut-off when not in use. This ensures the machine does not consume energy while idle and reduces energy costs for manufacturers.

More Time Efficient

CNC machines reduce more than physical waste in manufacturing. Time is valuable in this industry, and using CNC machines is time efficient. Cutting manually is time-consuming, and achieving a high level of precision requires years of experience. CNC machines execute tasks rapidly, often completing complex operations in a fraction of the time it would take a human worker.

Less Need for Reworking

In addition to working faster, CNC machines also turn out quality work. Thanks to the accuracy and consistency they offer, there is usually less need for reworking or fixing mistakes. This means workers can focus on other tasks that require human input, leading to increased productivity.

3 Benefits of Sustainability in CNC Machining

Adopting sustainable practices benefits your business in numerous ways. It improves cost savings and your brand reputation. We’ll explore the top three sustainability benefits of CNC machining.

Environmental Impact

Many people have environmental concerns and think about the negative impacts of manufacturing. Luckily, manufacturing companies can decrease their environmental footprint by using CNC machines to reduce waste. This machinery helps to preserve natural resources and reduce pollution in production.

Cost Savings

Adopting sustainable practices in CNC machining offers significant financial benefits. Although buying a CNC machine may seem like a considerable investment, it can save money in the long run. Since these machines maximize how you cut metal, you will save money on material costs over time.

Enhanced Brand Reputation

Sustainability positively affects a company’s image and brand perception. The public views companies that prioritize eco-friendly practices as responsible and forward-thinking. This positive image attracts customers who value environmental stewardship. A strong reputation for sustainability sets your company apart and builds trust with stakeholders.

Shop for CNC Machines

CNC machines offer numerous benefits in waste reduction, precision, and sustainability. Before investing in this essential technology, consider your cutting process, production volume, and budget.

Evaluate the Cutting Process

Evaluate your cutting process to choose the best CNC machine. Do you prefer plasma/oxy-fuel, waterjet, or laser? Each option has advantages, so select one that suits your production requirements based on the cutting processes you perform.

The process you use depends on the material you cut. For instance, a CNC laser cutting machine is ideal for stainless steel, while oxy-fuel CNC machines work best with mild steel.

Consider Production Volume

The CNC machine you choose must be able to handle your production volume. Consider how many parts you must produce within a certain time frame, and choose a machine with the appropriate capabilities.

Set a Budget

The cost of CNC machines varies depending on their size, features, and level of automation. Consider how much you are willing to invest in a CNC machine, and choose one that provides the best bang for your buck.

Prioritize the machine’s value. While some CNC machines have lower up-front costs than others, they may not offer the same long-term benefits as higher-quality, more expensive machines.

Buy From the Industry Experts

Koike Aronson has a century-long history of providing top-quality cutting solutions for various industries. Our team of experts can help you find the best computer numerical control machine for your needs, ensuring maximum efficiency and waste reduction in your manufacturing process. Buy a high-quality tool for your manufacturing company today!