Plasma vs. Laser vs. Oxy-fuel: Which One Is Right For You?

Posted by Koike Aronson, Inc. on Oct 29th 2024

Cutting metal is an essential task for numerous industries, and each method has its strengths and weaknesses. Three of the most common methods used in industrial settings are plasma cutting, laser cutting, and oxy-fuel cutting. This guide explores plasma, laser, and oxy-fuel cutting so you can determine which one is right for you.

What Is Plasma Cutting?

Plasma cutting uses ionized gas, or plasma, to slice through metal. Plasma is an electrically conductive and extremely high-heated gas. Metalworkers can use gases such as nitrogen, oxygen, and argon in plasma cutting.

During the cutting process, the gas reaches temperatures of nearly 40,000 degrees Fahrenheit when forced through the cutter’s nozzle. The plasma heats the metal to its melting point upon impact and then cuts through the material.

Industries Using Plasma Cutting

Plasma cutting has found widespread use in industries such as construction, automotive manufacturing, and metal fabrication due to its versatility and speed.

- The construction industry uses plasma cutters to fabricate steel beams, plates, and pipes, allowing for fast, precise cuts on-site.

- The automotive sector use plasma cutting to create everything from large frames to intricate engine components. This method’s precision ensures that all parts fit perfectly, contributing to the vehicle’s overall quality and safety.

- Plasma cutting is ideal for custom metal fabrication, making it a go-to tool for shops that need quick turnarounds on custom parts or prototypes.

Pros and Cons of Plasma Cutting

Weighing the pros and cons of plasma cutting can help determine whether this method is suitable for your operations.

The Pros

- High-speed cuts with precision, even on thicker materials.

- Can cut various metal thicknesses, making it highly adaptable.

- Lower upfront costs compared to laser cutting systems.

- Ideal for on-site work due to its portability and easy setup.

The Cons

- Since plasma cutters use high temperatures and electricity, they pose safety risks if you don’t handle them properly.

- Fumes and gases generated during the process require proper ventilation to protect workers and the environment.

- Plasma cutters are ineffective for wood or plastic materials, though they can handle most metals.

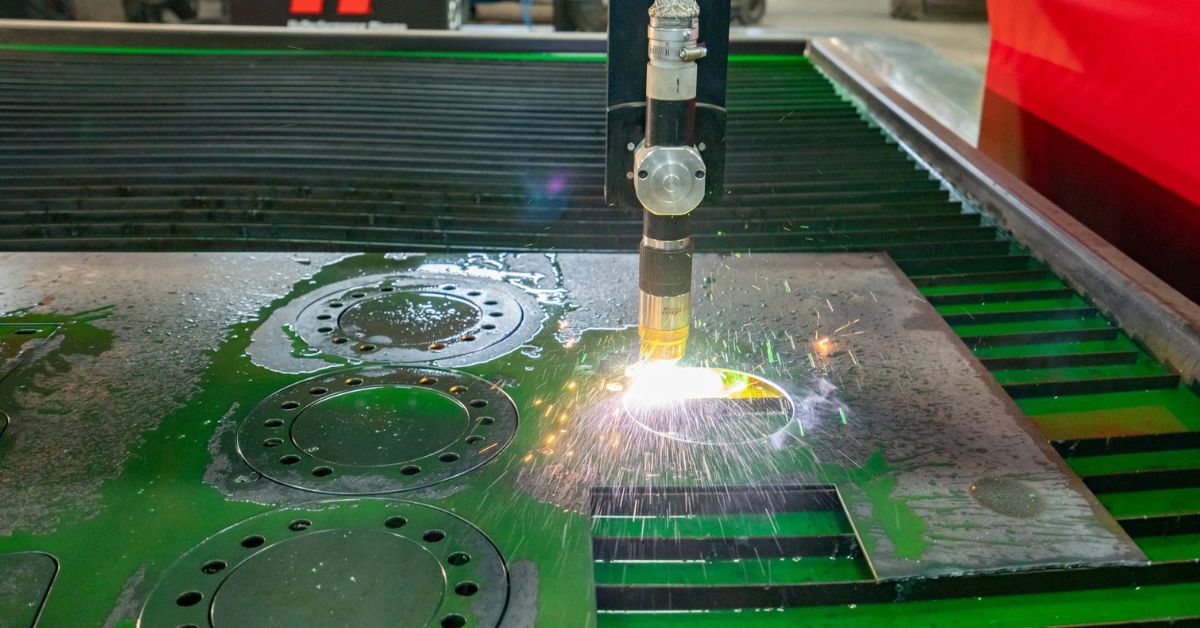

What Is Laser Cutting?

Laser cutting is a technology that uses a high-powered laser beam to cut through materials. The process involves directing the laser beam onto the material’s surface, which melts, burns, or vaporizes the material, creating a precise cut.

Two common types of laser systems are CO2 lasers and fiber lasers. Fiber lasers have high energy efficiency and can produce extremely fine, intricate cuts.

Key Features:

- Laser cutting is precise, making it ideal for cutting complex shapes and designs.

- Works well with a range of materials beyond metals, including plastics, wood, and textiles, though it has limited effectiveness on thicker metals.

Industries That Use Laser Cutting

Laser cutters can cut various materials, including metals, plastics, wood, and textiles. Its versatility makes it suitable for many applications, from industrial to artistic.

An Industrial Use of Laser Cutting

The aerospace industry benefits from laser cutting’s ability to produce lightweight and durable components. Aircraft manufacturers use this technology to create intricate parts that meet stringent safety and performance standards.

An Artistic Use of Laser Cutting

Experts can also use laser cutting to create intricate patterns and designs during metal fabrication projects. The precision and detail of laser cutting make it ideal for creating metal art pieces, jewelry, and decorative items.

Pros and Cons of Laser Cutting

Like other cutting forms, laser cutting has pros and cons that you should consider before deciding if it’s the appropriate method for your operations.

The Pros

- Laser cutting allows for precise, intricate cuts with minimal material waste.

- The laser beam moves quickly, resulting in faster production times and increased productivity.

The Cons

- Laser cutting is less effective on thicker metal plates (above a certain thickness, plasma or oxy-fuel may be more efficient).

- High initial investment.

- Laser systems can be hazardous without proper training and safety measures.

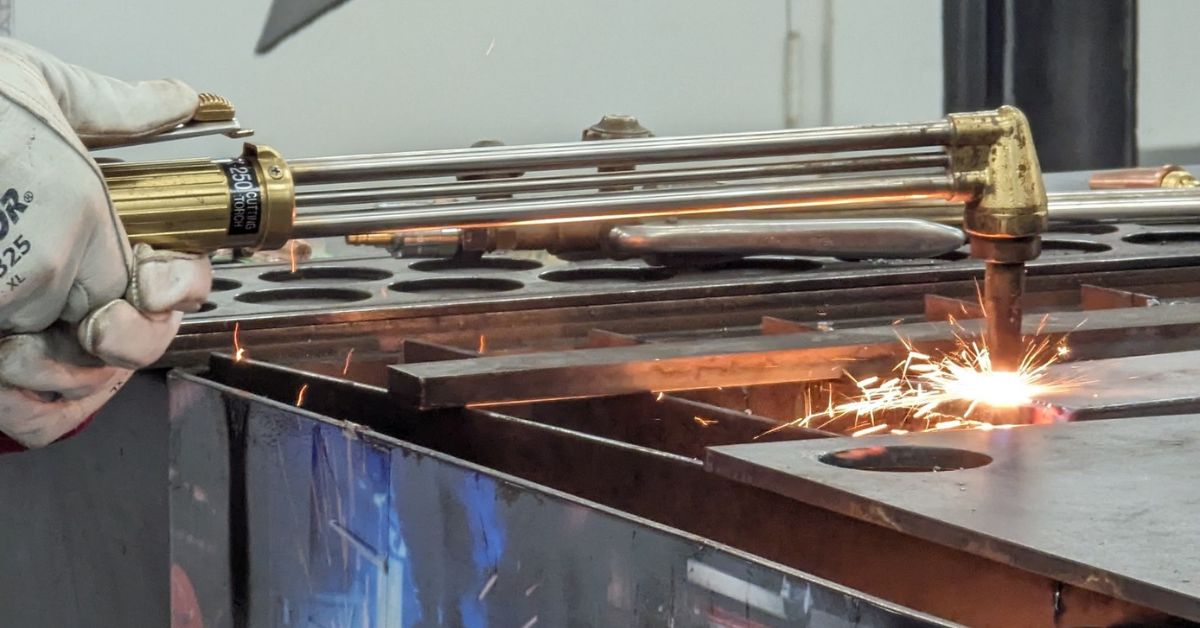

What Is Oxy-fuel Cutting?

Oxy-fuel cutting is a thermal cutting process that effectively slices through steel by utilizing a combination of fuel gas and pure oxygen. The method begins by generating a high-temperature flame through the combustion of a fuel gas—such as acetylene, propane, or natural gas—with oxygen. Metalworkers direct this flame onto the steel, rapidly heating it to its ignition temperature, causing the metal to oxidize and form iron oxide (slag). Once the steel reaches this temperature, the metalworker introduces a stream of pure, which reacts vigorously with the heated metal. This exothermic reaction produces intense heat, melting the steel and creating a localized molten area. The force of the oxygen stream blows the molten metal away, effectively cutting through the material. This process allows for precise and controlled cuts, making oxy-fuel cutting a widely used technique in various industrial applications for shaping and dismantling steel structures.

Industries Using Oxy-fuel Cutting

Workers primarily use oxy-fuel in heavy construction and industrial applications. It is ideal for cutting thick metal plates, especially carbon steel. This method is popular in construction, shipbuilding, and the oil and gas industry, where cutting thick steel is a regular task.

- Oxy-fuel is essential for cutting and shaping large steel beams and structural components in the construction industry.

- The shipbuilding industry uses oxy-fuel cutting for cutting thick steel plates used in constructing ship hulls.

- Oxy-fuel cutting is indispensable for oil and gas pipe-cutting operations, particularly in remote locations.

Pros and Cons of Oxy-fuel Cutting

The advantages and disadvantages of using oxy-fuel cutting are as follows:

The Pros

- Oxy-fuel cutting requires relatively low initial investments and operating costs.

- It’s ideal for cutting thick metal plates and can handle thicknesses that other methods may struggle with.

- Oxy-fuel equipment is lightweight, and workers can easily transport it to job sites, making it a convenient option for on-site work.

The Cons

- Compared to plasma or laser cutting, oxy-fuel cutting doesn’t always offer the same level of precision due to heat distortion, making it less suitable for intricate cuts or designs.

- Due to its nature, oxy-fuel cutting is slower than plasma or laser cutting, which can impact overall production times.

Which Method Should You Use?

Plasma cutting is best for shops needing fast, versatile cutting of various metals, from thin sheets to thick plates. Ideal for fabrication shops, automotive repair, and construction.

Laser cutting is ideal for projects requiring precision and fine detail, such as in the aerospace sector. It’s also perfect for industries that work with thinner materials or require tight tolerances.

Fiber laser cutting can efficiently handle thicker materials when paired with higher wattage power supplies, delivering precise cuts even on dense metals.

Oxy-fuel cutting is the go-to choice for heavy industries, such as shipbuilding and construction, where working with thick metal plates is the norm. This method excels in cutting thick steel and is a reliable, cost-effective option for field applications.

Shop at Koike Aronson

Koike Aronson is a leading manufacturer of cutting and welding equipment supplies. We have over 100 years of industry experience and can use our expertise to help you determine the cutting process and tools you should utilize. Purchase your machinery from a company committed to innovation and empowering its customers.