Shop Categories

-

Koike Aronson, Inc

ShopPro

The ShopPro is a high-performance cutting system made in the USA, offering fabricators premium features in a compact package designed to fit small shops. It's ruggedly built, ensuring the same reliability and accuracy found in all Koike Aronson cutting...Learn MoreLearn More- Available in 4'x4', 4'x8', 5'x10'

- CAD/CAM Pro Features

- 2" Table Capacity

- 45-125amp Plasma Systems

- Optional Oxy-Fuel, Scribe, and Pipe Rotater

-

Koike Aronson, Inc

ShopProXHD

The ShopProXHD represents the evolution of high-performance cutting machines, marking another stride in Koike Aronson's century-long legacy of excellence. Embodying the principles of "Built to Last," the ShopProXHD was eveloped in response to valuable...Learn MoreLearn More- Available in 4'x8', 5'x10', 6'x12'

- CAD/CAM Pro Features

- 2" Table Capacity

- 45-200amp Plasma Systems

- Optional Oxy-Fuel, Scribe, and Pipe Rotater

-

Koike Aronson, Inc

ShopProXHD Katana

The ShopProXHD Katana combines the industry-leading Koike design and manufacturing with the breakthrough Katana controller. Fitted with a fully integrated, UL Certified electrical panel and superior drive control components for greater precision and...Learn MoreLearn More- Available in 4'x8', 5'x10', 6'x12'

- Katana CNC with CAM Features

- 2" Table Capacity

- 200-400amp Plasma Systems

- Optional Oxy-Fuel, Scribe

-

Koike Aronson, Inc

PlatePro

The PlatePro: an affordable and user-friendly metal plate cutting machine designed to excel in limited spaces. This versatile machine harnesses the power of both plasma and oxy-fuel cutting technologies to deliver efficient metal cutting solutions...Learn MoreLearn More- 5', 6', and 8' Cutting Widths

- 10', 12', 20', and 24' Cutting Lengths

- Water or Downdraft Table Options

- 6" Table Capacity

- 45-200amp Plasma Systems

- Optional Oxy-Fuel, Scribe

-

Koike Aronson, Inc

MasterGraph Katana MGK

Introducing the MasterGraph Katana MGK, a state-of-the-art CNC oxy-fuel and plasma cutting machine designed to redefine precision, efficiency, and versatility in metal fabrication. Engineered with the same mechanical integrity as its predecessors,...Learn More -

Koike Aronson, Inc

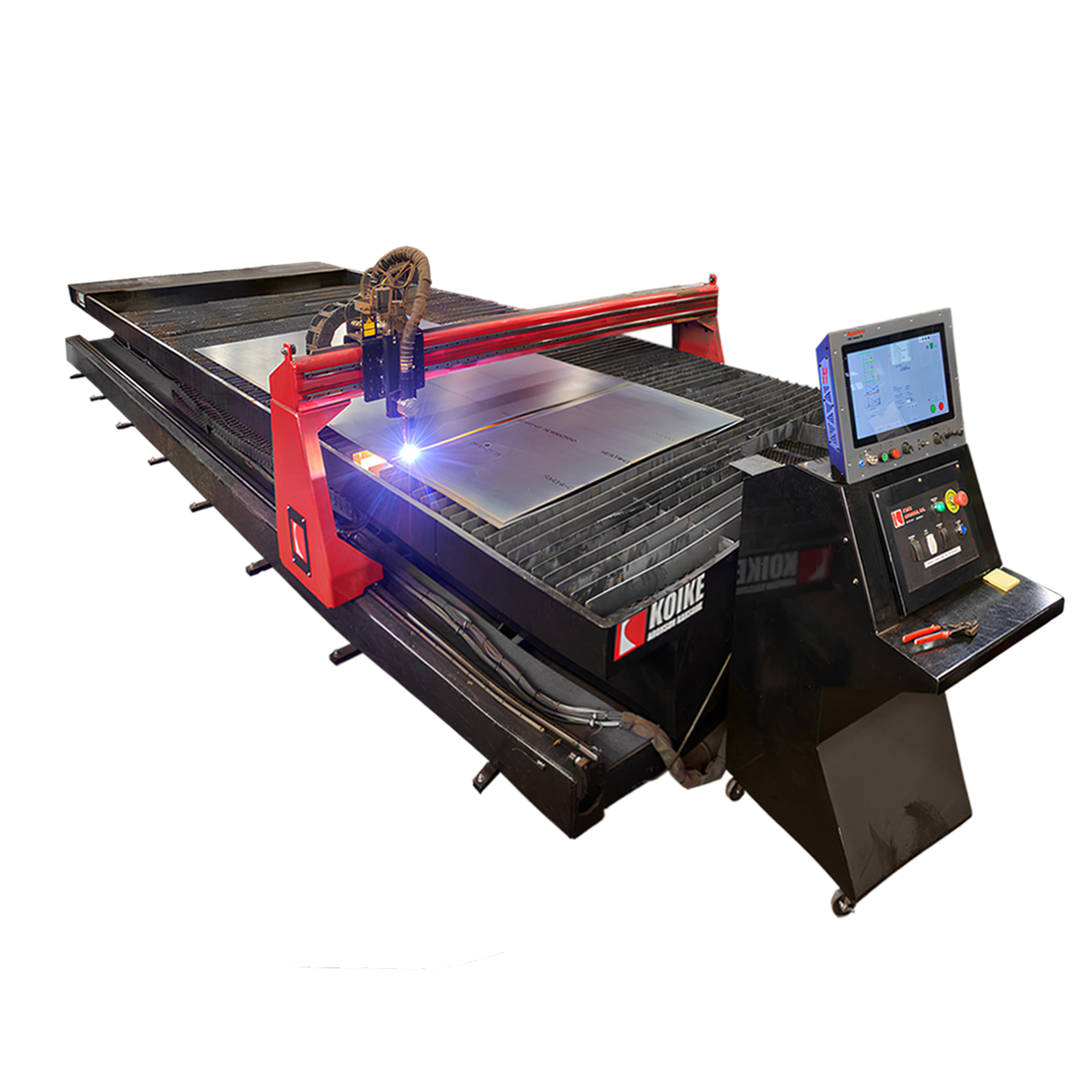

PlateProXHD

Engineered to meet the most demanding customer requirements, the PlateProXHD is designed to excel at thermal cutting, while remaining one of the most cost-effective machines in the indsutry. This automated dual side drive plasma/oxy-fuel cutting machine...Learn MoreLearn More- 6', 8', 10' and 12' Cutting Widths

- 10'-100' Cutting Lengths

- Water or Downdraft Table Options

- 8" Table Capacity

- 45-400amp Plasma Systems

- Optional Full Contour Plasma Bevel

- Optional Oxy-Fuel and Marking Station

-

Koike Aronson, Inc

Plate-Fab

The Plate-Fab from Koike Aronson, Inc. is a unitized design incorporating a downdraft or water cutting table. Engineered for increased precision and more options at a lower cost the Plate-Fab can be configured to cut plates sizes 5 or 6 foot wide by 10...Learn MoreLearn More- 5' and 6' Cutting Widths

- 10', 12', and 20' Cutting Lengths

- Water or Downdraft Table Options

- 2" Table Capacity

- 200-400amp Plasma Systems

- Optional Oxy-Fuel, Scribe

-

Koike Aronson, Inc

SuperGraph

The SuperGraph cutting system stands as a powerful solution, elevating your shop's productivity and consistency, potentially reducing material waste by up to 30%. Its remarkable traverse speed of up to 1000 inches per minute empowers you to maximize...Learn MoreLearn More- 6' and 8' Cutting Widths

- 10', 12', 20', and 24' Cutting Lengths

- Zoned Downdraft Table

- 1-1/2" Table Capacity

- 200-400amp Plasma Systems

-

Koike Aronson, Inc

MasterGraph EX2

The Mastergraph EX2 series, an industrial-grade, gantry-style thermal cutting machine engineered with cutting-edge technologies to thrive in the most demanding environments. This series epitomizes unmatched speed, performance, reliability, and...Learn MoreLearn More- 6', 8', 10' and 12' Cutting Widths

- 10'-100' Cutting Lengths

- Water or Downdraft Table Options

- 10" Table Capacity

- 200-800amp Plasma Systems

- Optional Full Contour Plasma Bevel

- Optional Oxy-Fuel and Marking Station

-

Koike Aronson, Inc

VersaGraph Extreme

The Versagraph Extreme, an exceptionally durable gantry-style thermal cutting machine designed to use the most advanced industry techniques including Finite Element Analysis (FEA). Engineered to excel in challenging environments and leveraging...Learn MoreLearn More- 8'- 24' Cutting Widths

- 10'-100' Cutting Lengths

- Water or Downdraft Table Options

- 12" Table Capacity

- 200-800amp Plasma Systems

- Optional Full Contour Plasma Bevels (x2)

- Optional Oxy-Fuel and Marking Station

Choosing the Right CNC Plasma Cutting Machine for Precision Fabrication

When precision fabrication is at the core of your business, selecting the right CNC plasma cutting machine is critical.

Gantry vs. Unitized Machines

The first decision hinges on your available space and operational focus.

- Gantry Cutting Machines feature a separated gantry system that travels over an external rail, making them ideal for large-scale shops requiring high-capacity cutting. These machines excel in handling extensive table lengths and dimensions, offering flexibility for larger projects.

- Unitized Machines combine the gantry and cutting table into one compact unit. These are perfect for shops with space constraints or smaller-scale businesses needing a reliable, high-performance cutter with simplified installation and maintenance.

Plasma vs. Oxy-Fuel Cutting

Determining the appropriate cutting method depends on the type of material and thickness you plan to cut.

- Plasma Cutting is renowned for its precision and speed, especially on thinner materials like steel, aluminum, and stainless steel. CNC plasma cutters work by creating an electrical arc through ionized gas, delivering clean, high-quality cuts at rapid speeds. Plasma systems typically range between 45 and 400 amps, making them versatile for diverse applications.

- Oxy-Fuel Cutting uses a combination of oxygen and fuel gases to cut through thicker steel plates efficiently. This method is particularly beneficial for heavy-duty applications where plasma cutting might struggle. If your projects often involve thick plate materials, oxy-fuel is a reliable choice.

Make the Right Investment

Innovation, precision, and efficiency start with the right tools. Ultimately, the perfect CNC plasma cutting machine depends on your business's unique needs. Whether it’s a highly versatile PlateProXHD for dual plasma/oxy-fuel capability or a space-saving ShopPro, investing in a machine tailored to your workflow will significantly improve the final product.