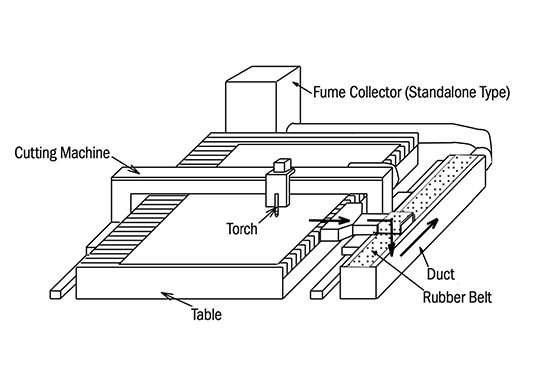

We've combined the industry-leading Koike design and manufacturing standard with a first-of-its-kind fiber laser cutting technology to welcome the FIBERTEX Zero into our robust industrial laser cutting machine lineup.

Thanks to the usage of Koike's 'K Type' cutting head, this large plate format DBC (Dual Beam Control) fiber laser boasts the highest level of contour accuracy for continuous wave (CW) cutting. From steel service centers, heavy equipment manufacturers, and shipyards, the FIBERTEX Zero CNC laser cutting machine was made to excel in the most demanding applications.