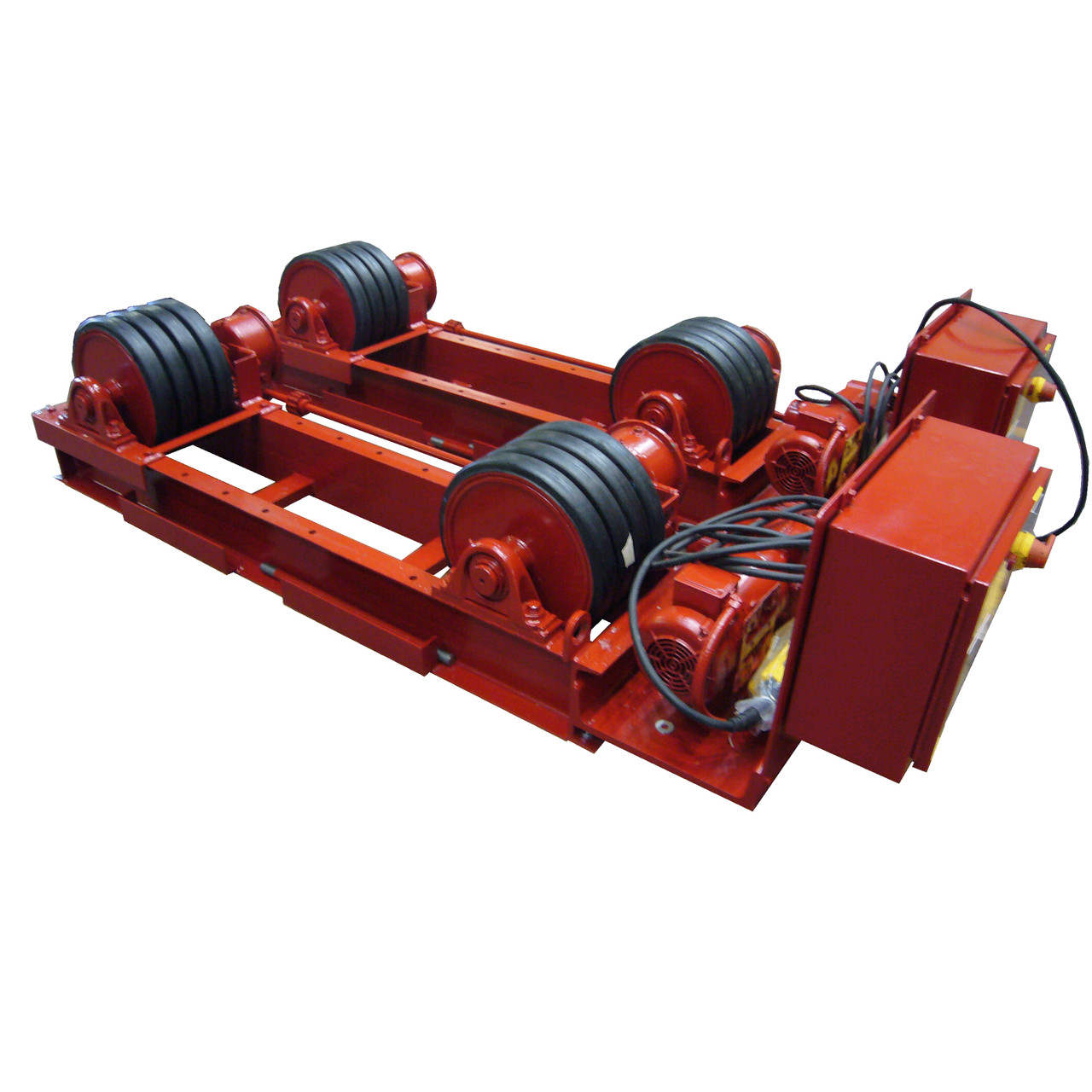

The Micarta Turbine Rotor Turning Roll ━ the smart and cost-effective alternative to industry standards like V-blocks. Whether it's for sonic inspection or welding repair, these specialty positioners simplify the process with cranes needed only for mounting and unloading. Once your turbines are on the Positioner, operators can effortlessly rotate and perform the required procedures.

What sets our Micarta Turning Rolls apart is the single fixed centerline setting, accommodating a wide diameter range to suit various rotor sizes. The phenolic wheels feature a hard, dense surface that won't damage the machined turbine journal, unlike steel rollers. Additionally, unlike rubber tires, Micarta doesn't deflect and effectively absorbs debris that could otherwise harm the rotor journal.

Powered by AC variable frequency drives and motors, the Micarta roll offers a wide range of rotation speeds while the standard hand-held operator pendant offer a simplified user expereience. Optional foot switch controls also available for your convenience.

Sub-base risers can be added for large diameter fins, providing ample swing clearance for a full 360-degree continuous rotation.

Features and Standard Equipment:

- Precision-Machined Phenolic Laminated Wheels:

- Housed within a rigid chassis to provide stable support and prevent end creep.

- Variable Speed Drives:

- Equipped with 50:1 variable speed drives for optimal control.

- Diameter Versatility:

- Able to accommodate workpieces from 8" to 32".

- Optional Fixed Height Sub-Bases.

- Optional Infinitely Adjustable Power Elevating Sub-Bases.