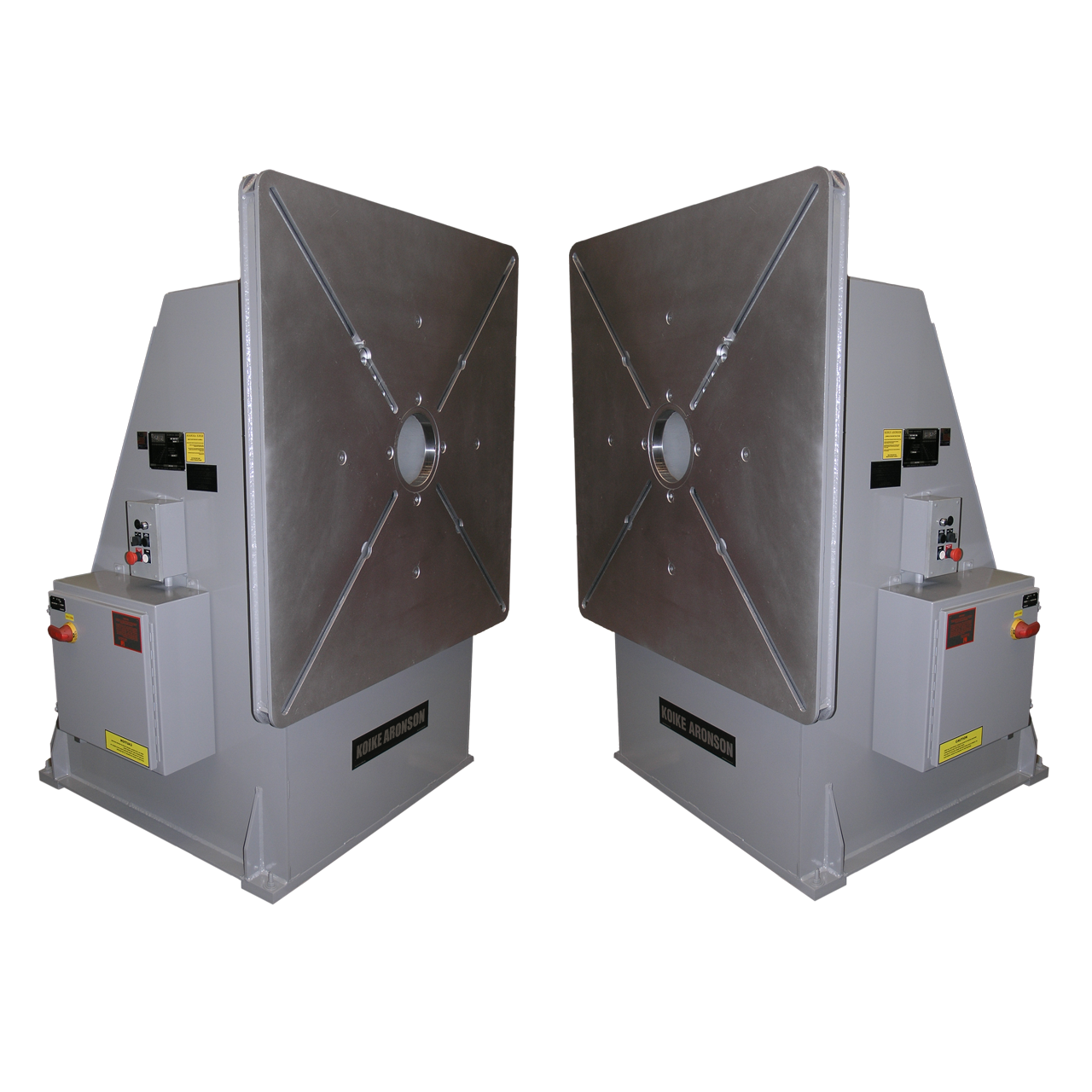

Fixed height Head and Tailstock positioners offer a wide range of capacities and customizable options, making them a practical solution for rotating long elliptical workpieces. When used together, these positioners occupy significantly less floor space compared to gear-driven counterparts of similar capacity. They can also function like a lathe, enabling precise rotation around the horizontal axis, facilitating high-quality welds while reducing production and handling costs.

Depending on the specific industrial application, these positioners may be mounted on a fixed base, manually adjustable base, or powered base, providing flexibility and efficiency.

Features and Standard Equipment:

- Piloted Tables for Centering Loads:

- Ensuring precise alignment and balance.

- Electrical Safety:

- NEMA 12 electrical components for enhanced safety and protection.

- Full Length Table Slots:

- Providing extended support for workpieces.

- Chassis Mounted Weld:

- Ensuring stable and secure welding operations.

- Current Grounding Blocks:

- Facilitating efficient electrical connections.

- Hand Control Pendants:

- Low voltage hand control pendants for precise operation.

- Variable Speed Drives:

- Equipped with 50:1 variable speed drives for optimal control.

- AC Brake Motors:

- Utilizes AC brake motors to enhance safety and control.