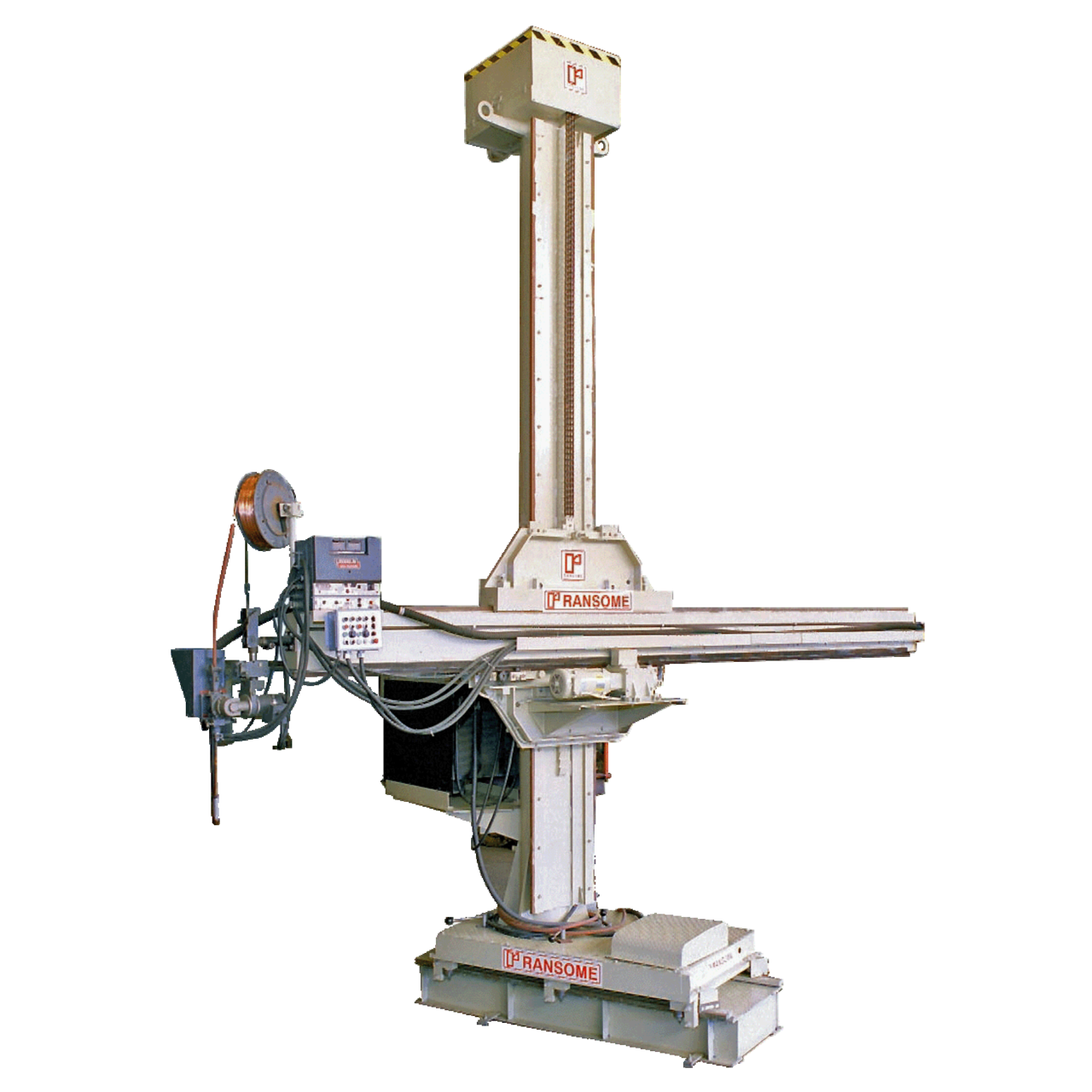

The Model 66, part of Koike Aronson's mid-range chain lift manipulator line, offers exceptional customization options tailored to specific applications, ranging from straightforward straight-line to intricate circumferential welding tasks. These manipulators are equipped with ram ends that can be outfitted with small I.D. single or multiple arc welding heads, making them ideal for tasks like long seam and circumferential welding procedures.

Our standard configurations for all manipulators include pedestal mounting, manual mast rotation, and the choice of powered rotation. However, we provide an extensive range of additional options, including self-standing bases, travel cars, and a diverse selection of welding equipment packages. These options allow you to fine-tune your manipulator precisely to meet the unique demands of your welding operations, optimizing both productivity and efficiency.

To offer you comprehensive welding solutions, you have the flexibility to select complete packages that we can supply and expertly mount, or you can provide your own equipment, which our dedicated team can also install. This adaptability ensures that your welding setup aligns perfectly with your requirements and workflow.

Features and Standard Equipment:

- Impressive Load Capacity:

- Supports up to 750lbs.

- Electrical Safety:

- NEMA 12 electrical components for enhanced safety and protection.

- Mast Rotation:

- Manual mast rotation for precise positioning.

- Variable Speed Drives:

- Equipped with 50:1 variable speed drives for optimal control.

- Precise Reach Control:

- Rack and Pinion Reach Drive System, allows for accurate and flexible positioning.

- Smooth and Accurate Movement:

- Inclusion of CAM Roller Guidance on both the lift and reach axes enhances precision and consistency in your welding operations.

- Reliable Lifting Mechanism:

- Reliable Chain Lift mechanism provides robust support for the manipulator's vertical movement, ensuring stable and secure handling of loads during various welding tasks.